Australia has experienced a concerning prevalence of substandard solar installations, leading to a range of negative consequences including reduced system performance, increased degradation, higher maintenance costs, and even safety concerns. Beam Solar is using internal audits of the installations on our platform as one of our tools to ensure they are of the highest standard.

Quality of Installations in Australia

The Australian National Audit Office (ANAO) conducted a report for the Australian Government, shedding light on the state of solar installations across the country. In this report audits conducted between 2016 and 2018 revealed that less than 20% of the audited solar installations were fully compliant with the necessary regulations. More specifically, over 20% of the audited sites exhibited significant issues that required rectification work to meet the standards. Furthermore, a staggering 60-70% of the audited sites contained minor or medium non-compliances, indicating a widespread lack of adherence to the necessary guidelines. Secondly, the Victorian Government's solar audits in 2021, through Solar Vic, discovered that a substantial portion of solar power systems installed in the state were substandard. Specifically, 36.85% of the audited systems required rectification, meaning they did not meet the necessary standards for efficient operation. Furthermore, a concerning 2.57% of the audited systems were assessed as outright "unsafe," posing potential risks to both the system owners and the surrounding environment.

The consequences of substandard solar installations are significant. Reduced system performance leads to diminished energy production, impacting the financial returns for system owners and the overall contribution of solar energy to the grid. Increased degradation further exacerbates this issue, reducing the lifespan of the system and increasing maintenance costs. Furthermore, safety concerns arise when solar installations fail to meet the necessary safety standards, potentially leading to electrical hazards or fire risks.

Beam Solar Internal Audits

One of the tools Beam Solar uses to ensure all solar power system installed through our platform are of the highest standard is our internal audits. Every install through our platform is audited by our in-house solar engineers.

In our audits we assess the entire system and create a report for the client highlighting all non-compliances with recommendations of how to rectify them. We can also send the installer the list of defects which need to be rectified and follow up ensuring they are completed.

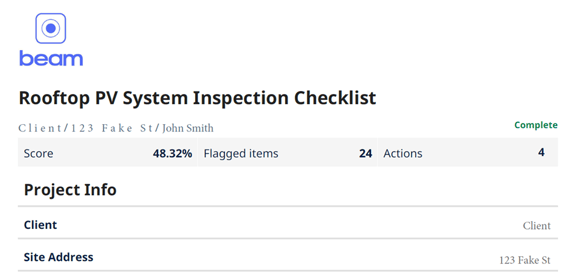

The non-compliances are split into 5 tiers; Safety Concerns, High Level Non-Compliances, Medium Level Non-Compliances, Low Level Non-Compliances and Opportunities For Improvement. The amount of and level of non-compliances found in the audit results in an installation score which is uploaded into our platform. An example of the audit score shown in the audit overview is below:

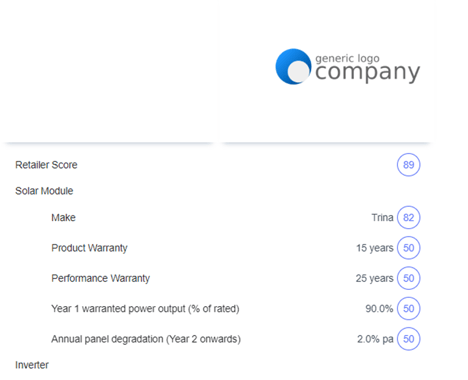

This audit score then affects the installers retailer score which future potential clients will be able to see when they are bidding on their projects. The retailer score has a weighting on the overall bid score and the likelihood of the retailer winning the contract. An example is shown below:

Safety Concerns

Safety Concerns are the highest level of non-compliance found in our audits. When a Safety Concern is found the client is immediately notified and the system is often turned off until the concern is resolved. The three main groups of Safety Concerns are substandard installations resulting in risk of fire, risk of electrocution and risk of equipment falling from the roof. Safety Concern findings include things such as:

- Incorrectly sealed DC junction boxes or isolators where water ingression can result in fire.

- Cables installed without sufficient current rating which can result in fire.

- Cables installed without sufficient over-current protection devices which can result in fire.

- Loose or incorrectly installed terminations or connectors which can result in fire.

- Exposed live conductors which can result in electrocution.

- Unsecured panels or other equipment which could fall from roof.

High Level Non-Compliances

High Level Non-Compliances are issues which can result in significant underperformance of the system, voiding of warranty of the equipment installed or causing damage to the building the system is installed on. When High Level Non-Compliances are identified the client is notified in the Audit report and the installer is required to rectify all defects. Common findings can include:

- Solar inverters installed without correct ventilation or in direct sunlight which increases their degradation and voids their warranty.

- Panel mounting equipment installed incorrectly or in an area not allowed by a structural engineering certificate voiding the warranty.

- Failure to use rubber stoppers between mounting equipment, cable trays, fastening equipment, your roof or other dis-similar metals which will result in premature rusting of the equipment or your roof.

- Poor system design resulting in underperformance, increased degradation or voided warranty.

- Incorrectly sealed roof or wall penetrations leading to water, dust or vermin ingression.

- Failure to provide correct documentation so the client can receive a Feed in Tariff or Renewable Energy Certificates resulting in reduced financial benefit to the client.

Medium Non-Compliances

Medium Level Non-Compliances typically can result in lower levels of underperformance or difficulties in operating or maintaining the system. These issues are highlighted to the client in the Audit Report and can be followed up with the installer upon client request. They can include:

- Minor system design issues resulting in underperformance.

- Insufficient walkways provided between panels or access to any equipment resulting in maintenance and operation difficulties.

- Failure to provide client with monitoring logins for system.

- Significant issues with system signage or documentation resulting in difficulties operating or maintaining the system.

- Some levels of shading on some panels resulting in minor underperformance.

- Installing panels too close to air-conditioning units or vents where heat can affect the performance or soot or grime can build up on the panels.

Low Level Non-Compliances

Low level Non-Compliances are cases where the installation is not entirely inline with required compliances but the risk of this causing issues with the system is low. These issues are highlighted to the client in the Audit Report and can be followed up with the installer upon client request. They can include:

- Issues with system signage which shouldn’t significantly affect the operation.

- Issues with system documentation which shouldn’t significantly affect the operation.

- Very minor design issues where resulting underperformance is negligible.

Opportunity for Improvements

Opportunity for Improvements are cases where the could have been completed to a higher standard but no issues with the system will result. We show these to the client in our report but typically do not follow up with the installers to fix. They can include:

- Messy conduit and runs not properly levelled.

- Messy system signage or documentation.

- Inverters installed close to office locations where the noise they produce could be annoying.

- Cable tray/ conduit routes going down walls visible from the street.

- Rubbish or debris from installation left on roof or inverter location.

Example of some audit results: